- Outras empresas da Fluke:

- Fluke

- Fluke Biomedical

- Fluke Networks

- Fluke Process Instruments

You Could Benefit from Pressure Calibration Automation Software More Than You Know – Here are Four Key Ways to Decide if it’s Right for Your Lab

Anyone performing pressure calibrations can benefit from automation. Whether you are using an automated pressure controller such as the 8270A or PPC4, or a fully manual deadweight tester, there is a lot you can gain, from time savings and increased process consistency, to adding value to your data and certification deliverables. In these times, when calibration technicians may be stretched thin, calibration lab managers should especially consider the value of automation to supplement the capabilities of their staff, while reducing errors and getting better data from tests. Want to know more about the value you can get from pressure calibration automation, and how to easily get started? Read on.

What is pressure calibration automation?

One can make an argument that using a pressure controller such as the 6270A or the 2271A, which you command to set a desired test pressure and maintain it without manual interaction, is automation. Beyond this, you can reap many additional benefits by automating more of the process using calibration software.

The level of automation you can achieve varies depending on the type of instrument you’re calibrating. Pressure calibration labs see instruments that vary from “visual feedback only”, to other instruments that provide electronic feedback, either through a data port or with an analog output to connect to a benchtop multimeter.

There are four basic common types of pressure instruments that we see in the calibration lab.

- Analog gauge with pointer, your typical dial gauges with no data port.

- Digital device with a display but no electronic data output.

- Digital device with a display and a data port.

- Transmitters and transducers with no display but rather an analog electrical output.

Some degree of calibration automation is possible for all these types of instruments, but the level of automation you can achieve varies depending on which one you’re testing. Pressure calibration automation means using software, such as COMPASS for Pressure, to fully or partially automate the calibration process of a device that reads pressure.

For example, when using a pressure controller as the reference, with some DUTs, such as the Fluke 750P, COMPASS can run an automated, unattended, end-to-end calibration; from taking as received data, calculating and writing new coefficients to the device, concluding with an as left run and then generating a customized calibration report. COMPASS can test multiple DUTs concurrently, further improving efficiency.

At the other extreme the devices must be read manually by an operator, but in these cases the software provides prompts to tell the operator what to do next and will automatically handle processing data and creating certificates of calibration at the end.

Pressure calibration automation is not procedure-based

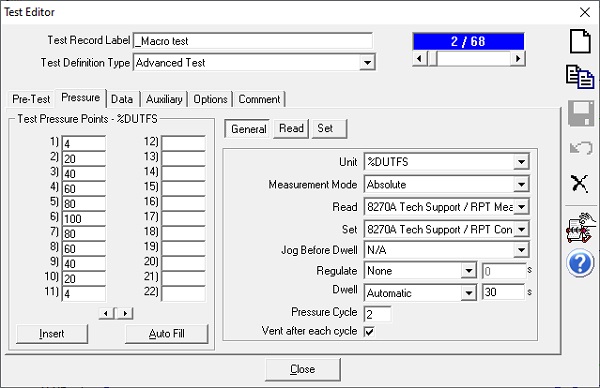

One of the most common objections I hear to automating pressure calibration is that calibration procedures aren’t very useful in the pressure world. MET/CAL, Fluke Calibration’s most well-known calibration automation software optimized for automating electrical calibrations, is procedure-based. COMPASS, however, doesn’t use procedures, and it doesn’t require users to understand scripting languages or drivers. Instead, COMPASS uses visually instructive setup windows that guide you through inputting test points and setting up your instruments. It’s visual and straightforward. Beyond setting up the reference device and DUTs, COMPASS also includes setups for additional instruments such as those that monitor ambient conditions, which COMPASS can also read electronically if the instruments communicate electronically.

How to determine if pressure calibration automation software is right for you

Now that we’ve discussed what pressure calibration automation is – and what it isn’t – I’d like to give you a simple framework to determine if automating pressure calibration is right for you. While these questions won’t determine the applicability for every user, these considerations will help you understand if the choice is a good one.

- If you typically test four or more points during a calibration. The more points you take during a calibration, the more justifiable it is to implement automation. Even if you’re calibrating analog dial instruments, you have the advantage of COMPASS prompting the user to input DUT information directly into the date file in real time, saving time that would otherwise later be spent manually inputting data.

- If you want to improve outcomes and reduce errors. In addition to saving operator time when you can run completely automated calibrations (freeing them up to perform other tasks while the automated run is taking place), process consistency is another important point to consider: Regardless of the level of automation, the testing sequence remains consistent.

- Automation can fill gaps when your workforce is stretched thin. With the new realities of the world we’re in, it’s even more important to consider process consistency. Staff may be reduced due either to social isolation factors or staff changes, or just the usual revolving door of new hires and retirements. With automation, no matter who the operator is, so long as they are trained on the software, you have a much higher probability of getting good, repeatable data from test to test.

- There’s a customer service benefit too. At the end of any calibration, what the calibration lab is providing – either to customers if they’re third party, or to the business if they’re first party – is a presentation of data. With COMPASS, you can generate customized calibration reports, and store multiple templates. You can also export data to Excel for further analysis and upload a PDF of the finished report to an asset management software solution.

Recommended products

6270A Pressure Controller/Calibrator

2271A Industrial Pressure Calibrator

8270A/8370A Modular High-Pressure Controllers/Calibrators

PPC4 Pressure Controller/Calibrator

7250LP Low Pressure Controller/Calibrator

What you need to get started with pressure calibration automation software

You can try out COMPASS for 60 days with a free trial, which has no functional restrictions. (If you end up committing to it, it will work as if you purchased it from the day you started the trial.) You need a computer that meets that system requirements, and any cables and interfacing that would be required to plug your devices under test into the computer.

You can also speak to myself or one of our experts to help you find the right solution, either by phone at 877-355-3224 or email me at jeff.grossman@flukecal.com. We also have extensive free online learning resources, including our brand-new Education Hub, filled with content you and your staff can consume at home, as well as live and on-demand webinars.

- Início

- Produtos

- Novos Produtos

- Calibração elétrica

- Calibração de RF

- Equipamento de aquisição de dados e de teste

- Calibração de temperatura

- Calibração de umidade

- Calibração de pressão

- Medidores de pistão

- Controlador/Calibradores

- Monitores de pressão

- Balanças de peso morto

- Calibradores manuais e monitores

- Handheld Pressure Calibrators

- Calibração de dados de aéreos

- Monitores ambientais

- Acessórios de calibração de pressão

- Sistemas personalizados de calibração de pressão

- Software de calibração de pressão

- Calibração de fluxo

- Ferramentas de Calibração de processo

- Software de calibração

- Serviço e suporte

- Todos os instrumentos de calibração

- Onde Comprar

- Notícias

- Treinamento e eventos

- Literatura e educação

- Serviço e Suporte

- Service Request (RMA)

- Planos de Serviço

- Suporte técnico

- Base de Conhecimento

- Acreditações

- Centros de assistência autorizados

- Calibration Certificates

- Community Forum

- My MET/SUPPORT

- Manuais de produto (Guias de usuário)

- Folhas de Dados de Segurança (SDS)

- Safety, Service, and Product Notices

- Downloads de software

- Sobre Nós